BioBased Lubricants: Beyond Esters

The Bio-based lubricants, derived from biological sources such as vegetable oils and animal fats, offer an eco-friendly alternative to traditional petroleum-based lubricants. They are primarily formulated from renewable resources, contributing to their sustainability and environmental appeal – but their use has been relatively rare. With external pressures forcing innovation in formulations, that might be all about to change.

Why Aren’t We Already Using Bio-Derived Oils?

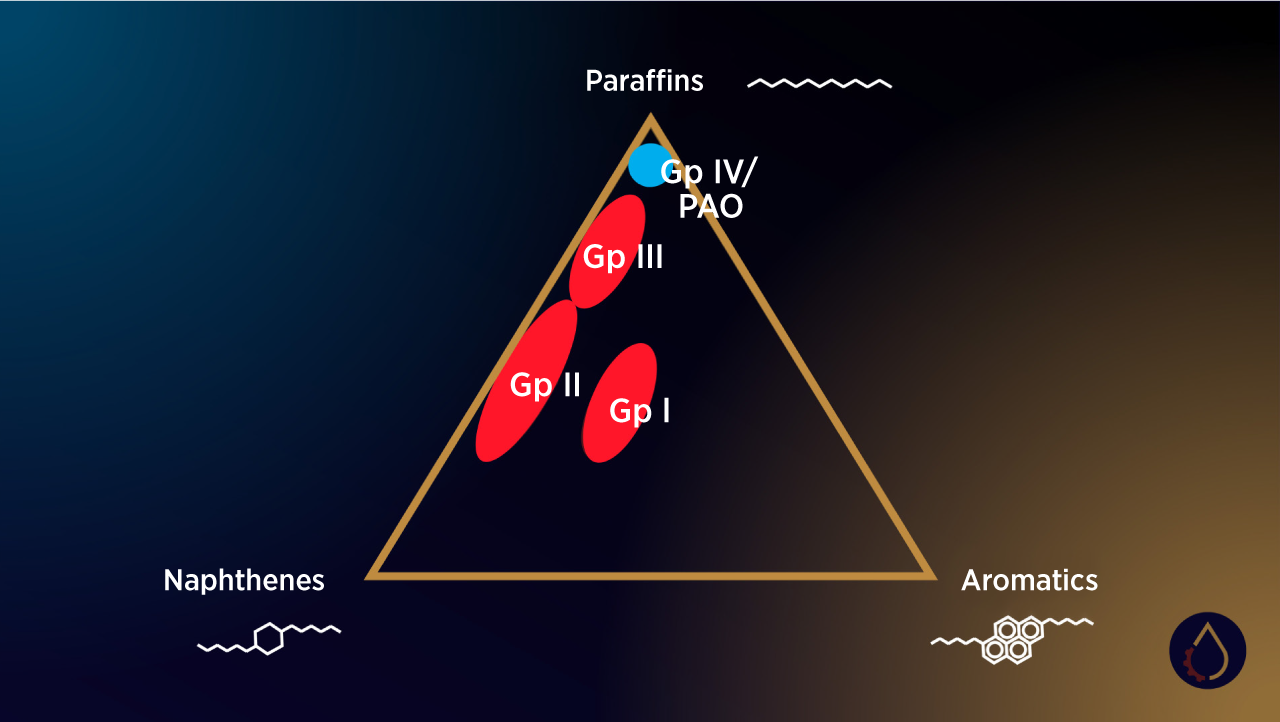

Mineral oils in the context of lubricants, are base oils derived from the refinement of crude oil. They are composed of various hydrocarbon molecules, with paraffin-type molecules being considered the most desirable. This is reflected in the API base stock groups, where Group I-IV correlates with total paraffin content. (Fig. 1)

Fig. 1: Typical molecular content of the API base stock groups

Crucially, mineral oils can be produced in a wide range of viscosities and grades, suitable for various applications. They generally exhibit good oxidative stability, meaning they can perform under a range of temperatures without significant degradation, and possess good lubricating properties, such as film strength and viscosity index.

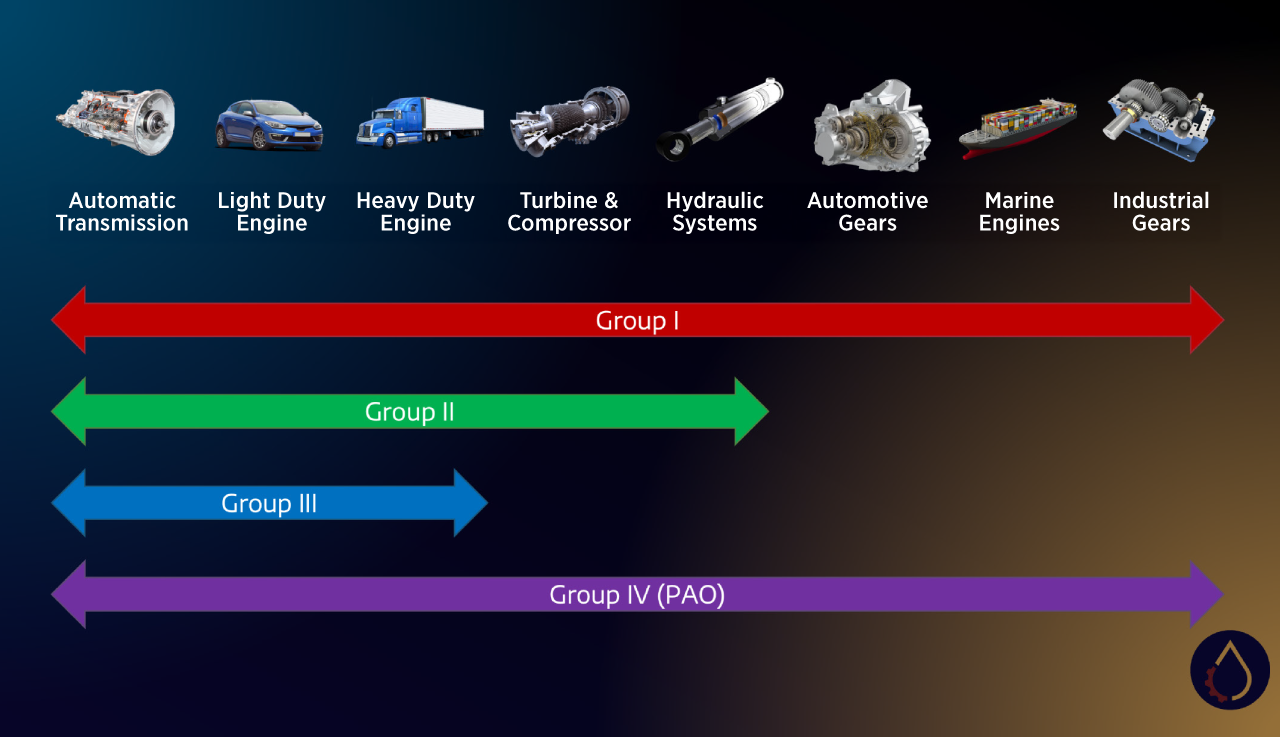

Most importantly, the scale of the petrochemical industry has made these products more cost-effective to produce than both synthetic and naturally derived oils, making them an economical choice for many applications. (Fig. 2)

Fig. 2: Typical application ranges for the API base stock groups

As a result of all these factors, mineral oils have been used for decades, providing a long history of reliable performance in a variety of applications, from automotive engines to industrial machinery.

A Pivot to a Greener Future

As with many other industries, the lubricants industry is looking to adopt bio-derived lubricants as a solution to reaching net zero. Stricter environmental laws worldwide, especially in Europe and North America, are pushing for the use of eco-friendly products. These regulations often target the reduction of carbon footprint and pollution, making bio-derived lubricants, which are generally more biodegradable and less toxic, a preferred choice. The EU’s EcoLabel initiative is the prime example of this, which governs the types of molecules that can be included in formulations, and at what concentrations.

There's also a growing global commitment towards sustainability. Bio-derived lubricants align with this trend as they are made from renewable resources, reducing dependency on finite fossil fuels and contributing to a circular economy. These commitments often come from lubricant end users who are increasingly aware of their environmental impact and are adopting greener practices to enhance their brand image and fulfill their CSR goals. Using bio-derived lubricants is seen as a proactive step in this direction.

Enter Bio-based Lubricants

The transition to bio-based lubricants presents a significant opportunity for the lubricants industry to contribute to decarbonization efforts. These lubricants, derived from renewable biological sources like vegetable oils and animal fats, inherently possess a lower carbon footprint compared to their petroleum-based counterparts. Their production involves the absorption of CO2 by the plants from which they are sourced, effectively capturing and reducing greenhouse gases from the atmosphere. Additionally, the biodegradability of bio-based lubricants minimizes environmental pollution and eases disposal issues, further contributing to a reduction in overall carbon impact.

However, not all bio-based lubricants are created equal. They’re primarily sourced from vegetable oils, like rapeseed, sunflower, soybean, and palm oil. These oils are extracted from seeds or fruits of plants and undergo processing to enhance their lubricating properties. In times gone by, tallow and lard were examples of animal fats used in some lubricant applications. However, vegetable oils are more commonly used due to sustainability and ethical considerations.

The current bio-based lubricants range is more-or-less split into three categories:

- Triglyceride-Based Lubricants: Derived from vegetable oils, these lubricants are composed of triglycerides, which are esters formed from glycerol and fatty acids.

- Ester-Based Lubricants: These are synthesized from bio-derived alcohols and acids. They offer better thermal stability and lower volatility compared to triglycerides.

- Polyalkylene Glycol (PAG) Lubricants: Made from bio-derived glycols, PAG lubricants offer excellent lubricity and are often used in applications requiring high thermal stability.

New Developments in Bio-Based Lubricants

As the lubricants industry evolves, alternative base oils are emerging as viable alternatives to traditional polyalphaolefins (PAOs) and mineral oils. Driven by advancements in technology and an increasing focus on sustainability, new molecules have emerged like Synnova, Estolides, and Ester-PAG hybrids (manufactured by Novvi, Biosynthetic Technologies, and VBase, respectively). In each case, the molecular structure of these seeks to overcome the weaknesses of our current bio-derived products.

Bio-based iso-paraffinic molecules like Synnova (currently made by Novvi) can be derived from renewable feedstocks. Formerly made from sugarcane derivatives the base oil production is carbon-negative, and the low molecular-weight variants are both 100% bio-based and 70% biodegradable by OECD 301b. Its performance characteristics closely mirror PAOs, although the pour point is slightly higher. What Synnova offers is the possibility of creating bio-lubricants without the use of esters, with characteristics that are more typical of standard PAO-synthetic oils.

Estolides are a variant of esters that use a property known as steric hindrance to shield the hydrolytically unstable part of the ester. By cloaking the “core” of the molecule in long chains, estolides offer all the benefits of synthetic, bio-derived esters without the traditional downsides.

Finally, novel ester-PAG hybrids such as those made by VBase, are offering high flash and fire points, giving an environmentally-conscious alternative to the phosphate esters typically used where fire-resistant fluids are required.

New Developments in Bio-Based Lubricants

As we enter a new era, where sustainability is put at the forefront of asset management decisions, more and more end-users are starting to demand that their lubricants are sustainably manufactured. Bio-derived products are a simple way to meet this need, although the future will likely see a mix of bio-derived, re-refined, and extended-life products.

About the Author

Rafe Britton is a distinguished mechanical engineer with 14 years of expertise in the lubricants industry, serving both as an operator and a supplier. He holds dual degrees in Aerospace Engineering and Physics from UNSW. Known for his popular YouTube channel and podcast, Rafe helps mid-size industrials enhance equipment uptime and cut lubrication costs. He is actively involved with several professional boards and holds multiple certifications, including ICML MLE and MLA III. Contact Mr. Rafe Britton at rafe@lubrication.expert

Rafe Britton

Technical Specialist | Lubrication Expert